The product has high requirements for flatness, contour, and mounting hole position accuracy. High-precision forming process capabilities and large-size product CMM detection capabilities are required to achieve production

It involves multiple processes such as blanking, stacking, welding, forming, trimming, and grinding. It requires joint design by senior technicians in various process fields to provide a mature process solution.

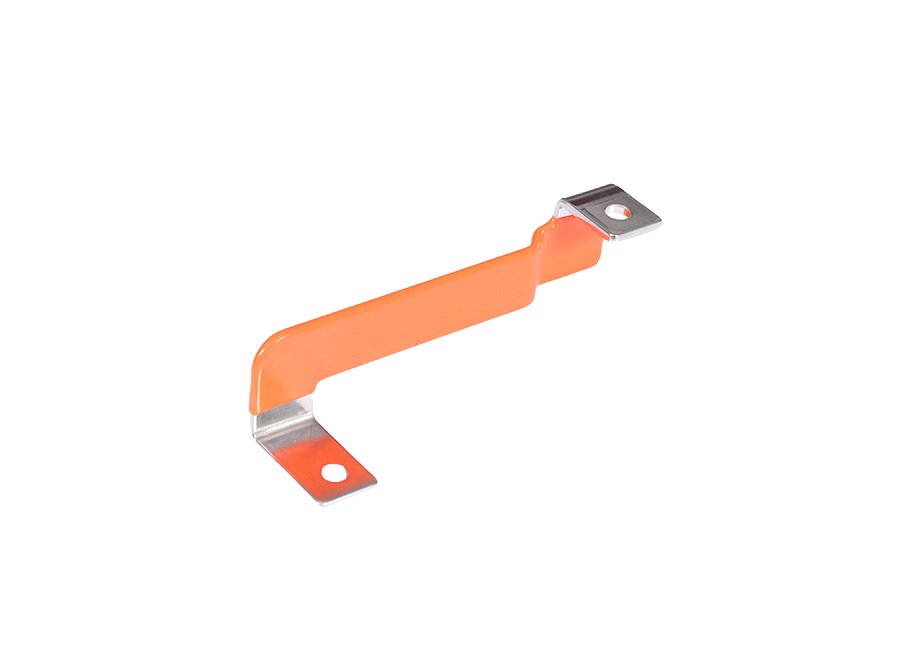

Copper busbars are essential components in power distribution systems and can provide reliable and efficient conduction methods for various applications. Copper busbars are made of highly conductive materials such as copper or aluminum, and are designed to reduce system losses and improve the performance of power distribution networks.

Lamination BUSBAR

Highlights at a glance:

Inquiry Now

add to cart

-

Product Details

-

related products

-

Inquiry Now

Product Details

Materials: T2/TU1 COPPER、AL1060、AL6101、heat shrink tubing、PVC、EVA、PA、PI

Processes:injection molding, dip molding, casing, spraying, extrusion thermoforming

Max. Temperature Resistance:Class 900°C (3H)

Surface treatment:Tin, Ni, Au, Silver plating

The laminated design provides a compact, robust solution that is easy to install and maintain. These busbars are resistant to high temperatures and mechanical stress, making them ideal for high-current applications. Whether for solar inverters, battery storage systems, or electric vehicle charging stations, our customized lamination busbars ensure long-lasting performance and optimal power delivery.